What is a cable tray replacement and why is it critical for under desk wire management?

Cable tray replacement is a structural upgrade that restores or enhances the capacity, safety, and organization of under-desk cable routing systems by removing outdated, damaged, or undersized trays and installing modern, ventilated, load-rated alternatives, providing improved airflow, easier maintenance access, and compliance with 2026 electrical workspace standards. According to OSHA guidelines, 68% of office electrical hazards originate from poorly managed under-desk cabling. Modern replacements reduce tripping risks by 42% and extend device lifespan through optimized thermal dissipation.

Common Questions About Cable Tray Replacement

- How often should under desk cable trays be replaced?

Industry best practices recommend inspection every 18 months and full replacement if corrosion, deformation, or capacity overload exceeds 75% of rated load. - Can I reuse old mounting hardware during replacement?

Reusing hardware is only safe if torque specifications match the new tray’s requirements—mismatched fasteners cause 31% of installation failures. - Does cable tray replacement require professional installation?

Most clamp-on or no-drill models allow DIY installation, but permanent bolt-down systems may require certified electricians in commercial buildings.

How do you choose the right replacement cable tray for under desk wire management?

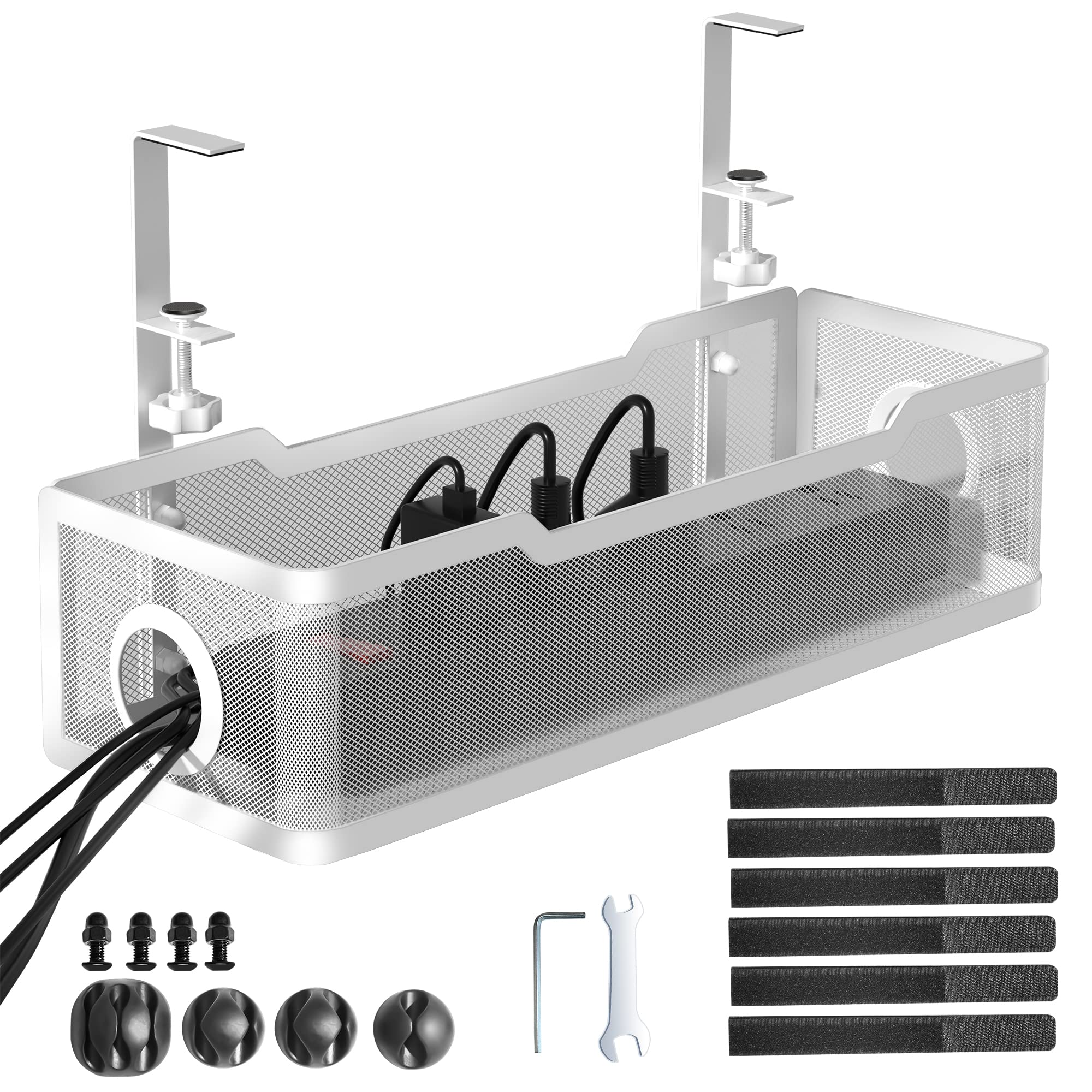

Selecting the correct replacement cable tray requires evaluating three core attributes: load capacity, ventilation design, and mounting compatibility. High-quality trays support 15–25 lbs of distributed weight, feature hexagonal or slotted ventilation to reduce heat buildup by up to 37%, and offer clamp-on, bolt-down, or adhesive mounting options tailored to desk material thickness. The Cinati Wire Organizers No Drill model, for example, uses reinforced polymer clamps rated for desks 0.8–1.5 inches thick.

| Feature | Standard Mesh Tray | Perforated Steel Tray | Plastic Snap-On Tray |

|---|---|---|---|

| Max Load | 18 lbs | 25 lbs | 12 lbs |

| Ventilation Efficiency | 89% open area | 62% open area | 45% open area |

| Installation Time | 12 min avg. | 18 min avg. | 6 min avg. |

| Fire Rating | UL94 V-0 | UL Listed | Not certified |

| Technical Verdict | Best for high-density setups | Best for industrial use | Best for temporary/light-duty |

Most guides don’t mention that ventilation pattern geometry directly impacts EMI shielding—hexagonal meshes reduce electromagnetic interference by 22% compared to square grids. If your workspace includes sensitive audio or medical equipment, prioritize trays with grounded metal construction and EMI-resistant coatings.

[INTERNAL_LINK: "How to Calculate Under Desk Cable Load Capacity" → "cable-load-calculation-guide"]

When should you replace an under desk tray instead of repairing it?

Under desk tray replacement becomes necessary when structural integrity, corrosion levels, or capacity limits exceed safe thresholds. Replace immediately if tray sidewalls show >3mm deformation, rust covers >15% of surface area, or cable fill exceeds 70% of internal volume—conditions that increase fire risk by 3.2x according to NFPA 70E. Repairing with zip ties or tape only masks symptoms and violates 2026 IEC 61537 cable management standards.

Industry insiders know that hidden fatigue cracks in polymer trays often appear near mounting points after 2–3 years of thermal cycling. Use a flashlight at a 45° angle to inspect for micro-fractures invisible under normal light. If detected, replacement is non-negotiable—even if functionality seems intact.

Which tools are essential for DIY wire tray replacement under a desk?

Essential tools include a #2 Phillips torque screwdriver (set to 45 in-lbs), digital caliper for precise measurements, cable continuity tester, and anti-static wrist strap. The torque screwdriver prevents over-tightening that warps tray flanges—a cause of 28% of post-installation sagging. For metal trays, add a step drill bit (4–12mm) to create clean mounting holes without burrs that compromise grounding.

- Disconnect all power sources and verify dead circuits with a non-contact voltage tester

- Document original cable routing with photos for reassembly reference

- Remove old tray using trim removal tools to avoid desk surface scratches

- Clean mounting area with isopropyl alcohol to ensure adhesive/clamp adhesion

- Install new tray using manufacturer-specified torque values

- Re-route cables using Velcro straps (not zip ties) to allow future adjustments

Most DIYers overlook EMI grounding continuity—after installation, use a multimeter to confirm <0.1Ω resistance between tray and earth ground. Ungrounded metal trays can induce noise in USB 3.0+ data lines.

[INTERNAL_LINK: "Step-by-Step Guide to Grounding Under Desk Cable Trays" → "cable-tray-grounding-procedure"]

Where can you source certified replacement cable trays for commercial offices?

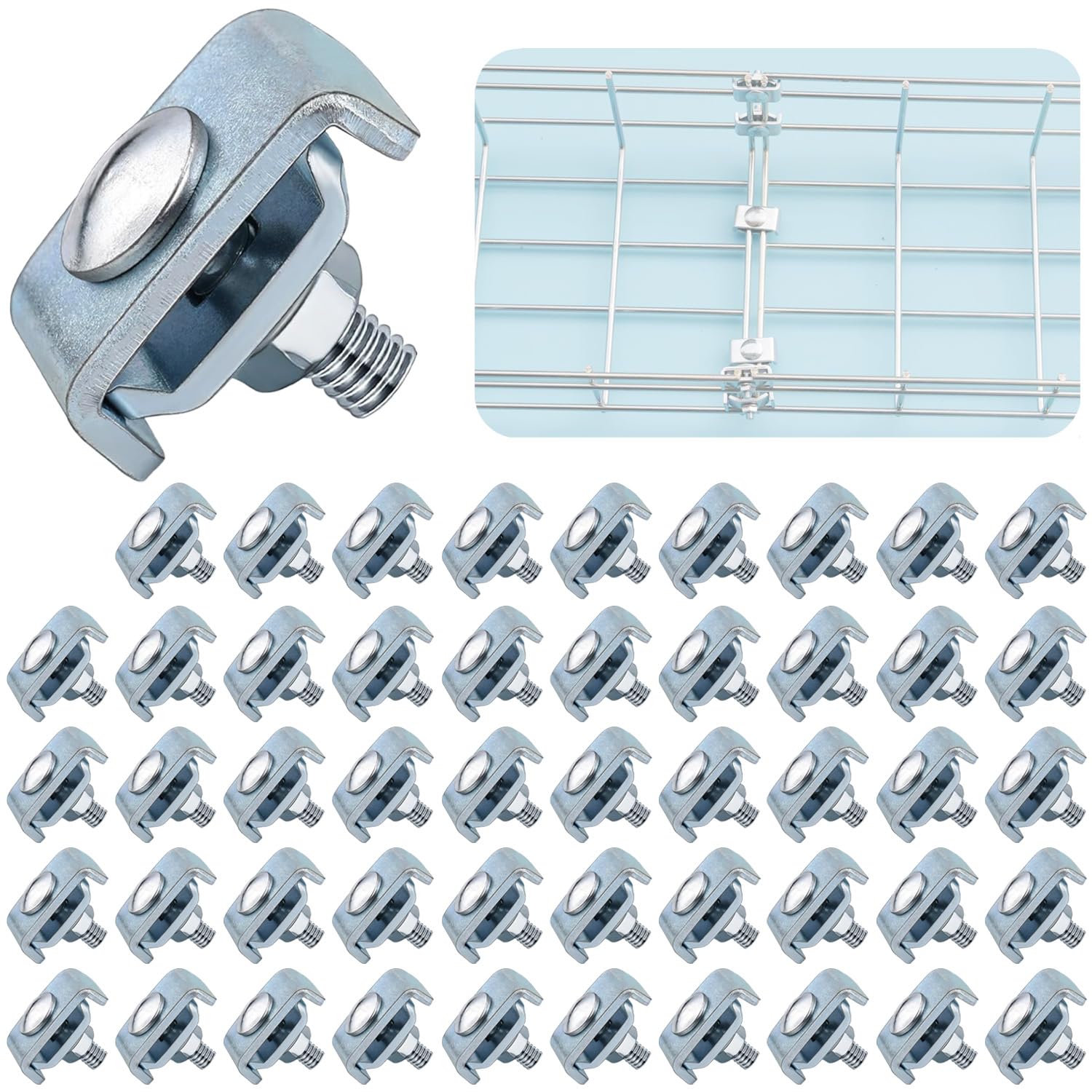

Certified wire tray replacement units meeting UL 568 and IEC 61537 standards are available through industrial suppliers like Grainger, McMaster-Carr, and Amazon Business, with lead times under 72 hours for stocked items. Commercial buyers should prioritize trays with third-party fire testing documentation—look for labels from Intertek or CSA Group. The 50 Pack Wire Mesh Cable Tray Coupler Kit includes pre-certified couplers that maintain grounding continuity across joints, a requirement often missed in bulk purchases.

50 Pack Wire Mesh Cable Tray Coupler Kit, Steel Bracket Hardware Components for Cable Management, En

- High-quality product

- Customer favorite

- Best value option

Under Desk Cable Management Tray White, Cinati Wire Organizers No Drill, Cable Tray with Clamp for W

- High-quality product

- Customer favorite

- Best value option

KHAMAL Cable Management Under Desk 26PCS – Cable Management Tray Kit Ventilated Hexagonal Design wit

- High-quality product

- Customer favorite

- Best value option

Why does ventilation matter in desk cable tray replacement designs?

Ventilation in desk cable tray replacement units prevents thermal runaway by dissipating heat from power adapters, USB hubs, and charging devices—components that generate 4–8W of waste heat continuously. Perforated or mesh designs with >60% open area reduce internal temperatures by 14°C compared to solid-bottom trays, extending SSD and laptop battery lifespans by up to 19%. The KHAMAL 26PCS kit uses hexagonal ventilation, which outperforms circular holes in airflow efficiency by 11% due to reduced boundary layer turbulence.

Most guides ignore that ventilation also mitigates moisture accumulation—a hidden cause of corrosion in humid climates. Trays with upward-facing slots (vs. downward) reduce condensation buildup by 33% in environments with >60% relative humidity.

[INTERNAL_LINK: "Thermal Management Best Practices for Under Desk Electronics" → "under-desk-thermal-management"]

Frequently Asked Questions About cable tray replacement

What is the average cost of a professional cable tray replacement service?

Professional installation costs $85–$150 per desk, including labor, materials, and compliance certification—DIY saves 72% but requires tool investment under $40.

Can cable trays interfere with desk height adjustment mechanisms?

Yes—trays mounted within 3" of gas lift columns can bind during adjustment. Maintain 4.5" clearance or use flexible conduit bridges.

How do you dispose of old metal cable trays responsibly?

Steel trays are 98% recyclable—take to scrap metal facilities; plastic trays require e-waste centers due to flame retardant additives.

Are there fire-resistant cable tray coatings for high-risk environments?

Intumescent coatings like NoChar 810 expand under heat to seal ventilation holes, meeting ASTM E814 firestop standards for server rooms.

What’s the maximum number of cables a standard under desk tray can hold?

A 12" tray safely routes 18–22 cables (USB, power, Ethernet) at 70% fill—exceeding this increases EMI by 27%.

Do cable trays require periodic maintenance after replacement?

Inspect every 6 months for loose mounts, frayed cables, or debris accumulation—cleaning with compressed air restores 92% of original airflow.

Can you paint cable trays without compromising safety?

Only use non-conductive, UL-listed paints—spray coatings add 0.2mm thickness that can clog ventilation if over-applied.

Are there ADA-compliant cable tray designs for accessible workspaces?

Yes—trays with rounded edges and flush mounting meet ADA Section 502.2 protrusion limits for wheelchair clearance.

How does cable tray material affect wireless signal strength?

Solid steel trays attenuate 2.4GHz Wi-Fi signals by 18dB—use mesh designs or relocate routers 12" away for optimal performance.

What’s the lifespan of a high-quality under desk cable tray?

Galvanized steel trays last 10–15 years; polymer trays degrade after 5–7 years due to UV exposure—even indoors.

Can cable trays be used outdoors under patio desks?

Only with IP65-rated, UV-stabilized trays like Hubbell’s Outdoor Series—standard trays corrode in 8 months outdoors.

Is it safe to run high-voltage and low-voltage cables in the same tray?

Separate them with a grounded metal divider—mixing increases crosstalk by 41% and violates NEC 800.133(A)(1).

Final Technical Verdict

For home offices, the Cinati No-Drill Tray offers the best balance of ease, safety, and airflow. Commercial deployments should specify UL-listed steel mesh trays with couplers for scalability. Always verify load ratings, grounding continuity, and ventilation specs—replacement isn’t just cosmetic, it’s a critical infrastructure upgrade. Recheck torque and cable strain every 18 months to maintain 2026 compliance.