Understanding the Anatomy of Failure: Why Your Vacuum Stopped Working

There is a specific, visceral frustration that occurs when you are mid-clean, and you realize your vacuum is no longer performing its primary function. You see the debris on the carpet; you hear the motor whirring with its usual intensity, yet the floor remains stubbornly dirty. This phenomenon—a vacuum not picking up—is more than a minor inconvenience; it is a breakdown in a precisely engineered pneumatic system. As a homeowner, your first instinct might be to assume the motor has died or that the unit requires a costly replacement. However, in over 90% of cases, the issue is not a terminal mechanical failure, but rather a breach in the airflow logic that governs how these machines operate.

A vacuum cleaner is, at its core, a pressure-differential machine. It creates a low-pressure zone inside the housing, forcing higher-pressure atmospheric air to rush in, carrying dust and debris along with it. When you experience vacuum no suction, you are witnessing a disruption in this delicate balance. This guide is designed to move beyond the superficial advice found in standard manuals. We are going to dissect the physics of suction, the mechanical bottlenecks common to modern uprights and sticks, and provide a systematic methodology for restoring your machine to factory-level performance.

The modern vacuum has evolved from simple suction boxes to complex filtration systems involving HEPA seals, cyclonic separators, and motorized agitators. While these advancements have made our homes cleaner, they have also introduced more "points of failure." A single hairline crack in a hose, a microscopic layer of fine dust on a pre-motor filter, or a tangled thread on a brush roll can reduce efficiency by half. Understanding that your vacuum is a closed-loop system is the first step toward mastery. If air cannot get out (due to a clogged filter), air cannot get in (the suction dies). If the path is blocked (a clog), the pressure drops. If the seal is broken (a leak), the energy is wasted. By the end of this guide, you will possess the expert knowledge required to diagnose and repair any vacuum on the market, saving hundreds of dollars in unnecessary replacements.

The Critical Problem: The Physics of Airflow and Mechanical Resistance

To solve the mystery of a vacuum not picking up, one must first understand the "Critical Airflow Path." Expert technicians look at a vacuum not as a single tool, but as a series of interconnected chambers. The problem usually falls into one of three categories: Airflow Obstruction, Seal Degradation, or Mechanical Resistance.

The Airflow Obstruction (The "Exhale" Problem)

Most users focus on the "intake," but the "exhaust" is equally vital. A vacuum is an air-pump. If the air cannot exit the machine through the exhaust filters, it creates backpressure. This backpressure prevents the motor from drawing in new air at the nozzle. This is why a vacuum might sound higher-pitched when it's "clogged"—the motor is spinning faster because it isn't actually moving any air; it's spinning in a partial vacuum. This is a primary cause of vacuum no suction. Fine dust, particularly from drywall or fireplace ash, is the silent killer here. These microscopic particles bypass the primary bin and coat the pores of the HEPA filter, effectively suffocating the machine.

Seal Degradation (The "Leak" Problem)

Suction is entirely dependent on a vacuum's ability to maintain a sealed environment from the floor head to the motor. Over time, rubber gaskets dry out, plastic clips lose their tension, and hoses develop pinhole leaks. A leak as small as a quarter-inch can result in a 30% loss in lift. This is particularly prevalent in "Lift-Away" or "Duo-Clean" models where the machine is designed to be disassembled frequently. Every connection point is a potential site for a pressure drop. If the "click" isn't crisp when you reattach a component, you are likely losing the pneumatic seal required to lift heavy debris or pet hair from deep carpet fibers.

Mechanical Resistance (The "Agitation" Problem)

Sometimes the suction is perfectly fine, but the vacuum is not picking up because the mechanical interface with the floor has failed. This is the "Agitator" or "Brush Roll" issue. In many modern homes with high-pile carpets, suction alone isn't enough to lift debris; you need the mechanical energy of a spinning brush to flick the dirt into the airstream. If the belt is stretched, the brush roll bearings are seized with hair, or the motor-to-brush transmission has failed, the vacuum will simply glide over the surface. It will "breathe" just fine, but it won't "scrub." Distinguishing between a suction problem and an agitation problem is the hallmark of an expert troubleshooter.

Methodology & Core Guide: The Universal Troubleshooting Protocol

To fix a vacuum not picking up, follow this high-performance protocol. This methodology is designed to be universal, applying to brands ranging from Dyson and Shark to Miele and Bissell.

Phase 1: The Collection Vessel and Primary Filtration

The most common culprit is also the simplest.

- The Max Fill Line: For bagless vacuums, never let the debris exceed the "Max" line. Once the debris reaches the internal cyclones, the centrifugal separation fails, and dust is forced directly into the filters.

- The Bag Integrity: For bagged vacuums, a bag that "looks" half-full may actually be "full" if you have been vacuuming fine dust. The pores of the bag become blinded, stopping airflow. If the bag feels firm or "rock-like," replace it immediately.

- The Pre-Motor Filter: Located usually directly under the dust bin or before the motor housing. Wash this in lukewarm water (no soap) and—critically—allow it to dry for 24 to 48 hours. Using a damp filter is the fastest way to destroy a vacuum motor.

Phase 2: Clearing the Airflow Conduit

If the filters are clean but you still have vacuum no suction, the blockage is in the "plumbing."

- The "Visual Pass": Drop a coin or a heavy marble through the hose. If it doesn't come out the other end, you have a clog.

- The Elbow Joint: Check the lower duct—the small, often clear hose near the floor head. This is the #1 site for clogs (socks, coins, or clumps of pet hair).

- The U-Bend: Use a bent coat hanger or a specialized "drain snake" to clear the internal piping of the vacuum body. Be gentle; you do not want to puncture the plastic lining.

Phase 3: The Floor Head and Agitator Maintenance

If the vacuum has suction at the hose but isn't picking up from the carpet, the issue is at the ground level.

- The Hair Wrap: Use a pair of scissors or a seam ripper to cut away hair, thread, and carpet fibers wrapped around the brush roll. This friction slows the motor and prevents the bristles from reaching the carpet backing.

- The Drive Belt: If your brush roll isn't spinning, check the belt. If it's snapped, replace it. If it’s "stretched," it may still spin when the vacuum is lifted, but it will stop the moment it touches the carpet.

- Height Adjustment: Ensure the vacuum isn't set too high (where it misses the debris) or too low (where it creates a "seal" against the floor, preventing air from flowing under the nozzle).

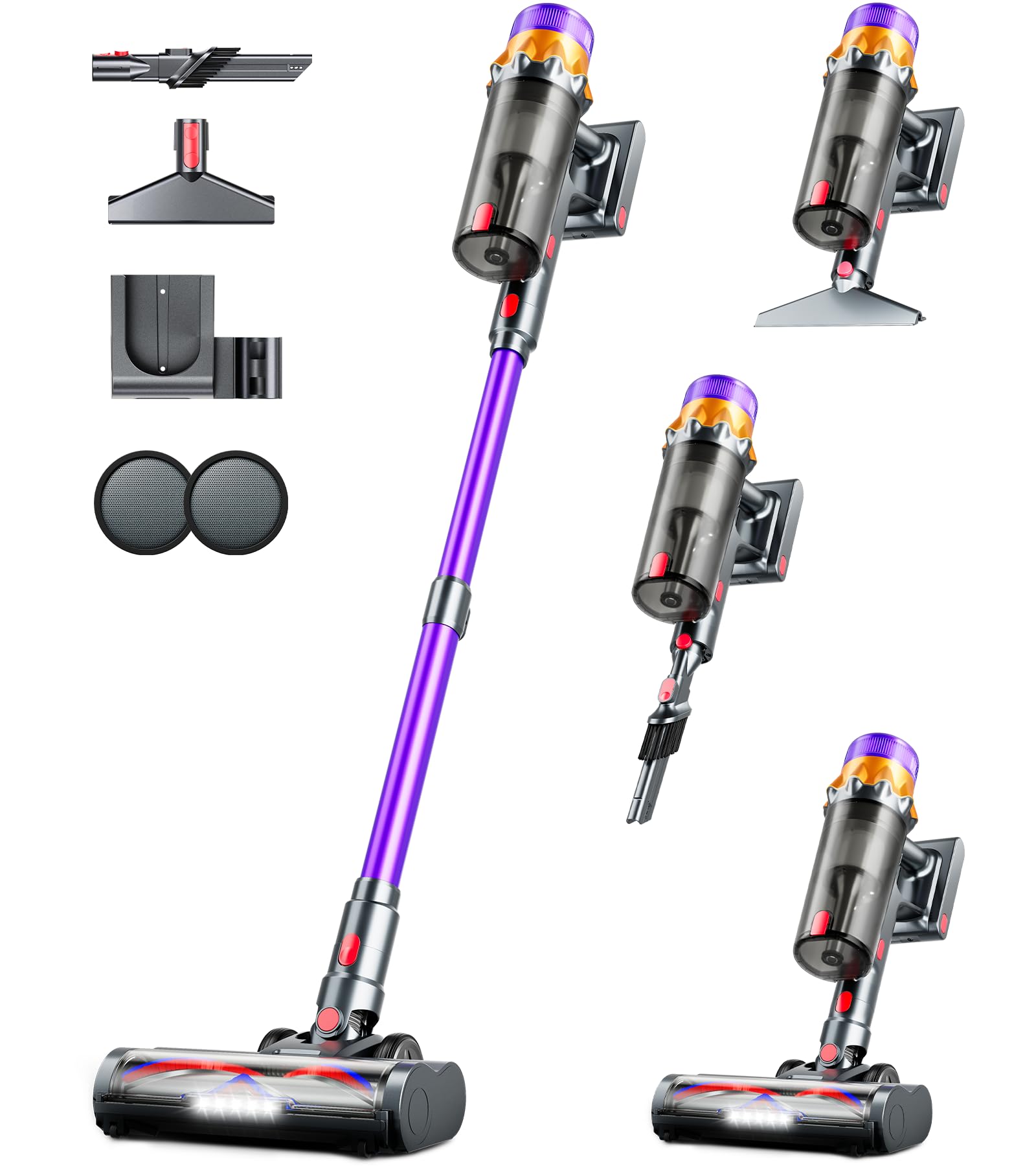

Cordless Vacuum Cleaner, Upgraded 55KPA 650W 70Mins Stick Vacuum with Hurricane Mode, Self-Standing,

- High-quality product

- Customer favorite

- Best value option

Cordless Vacuum Cleaner, 650W 55KPa 70Mins Vacuum Cleaners for Home, Self-Standing Stick Vacuum with

- High-quality product

- Customer favorite

- Best value option

Cordless Vacuum Cleaner, 500W 50KPA 60Mins Vacuum Cleaners for Home, Self-Standing Stick Vacuums wit

- High-quality product

- Customer favorite

- Best value option

Expert Hacks & Maintenance: Advanced Restoration Techniques

Once you have mastered the basics of clearing clogs and washing filters, you can move into advanced maintenance. These "hacks" are used by professional restoration teams to keep high-use equipment running for decades.

The Soleplate Waxing Hack

If you have a hard floor vacuum that is leaving behind fine dust, the issue may be friction. Clean the "soleplate" (the bottom of the vacuum) with a micro-fiber cloth and a tiny amount of silicone spray or furniture polish. This reduces the static charge that causes dust to cling to the plastic instead of being sucked into the intake.

Restoring Brush Roll Bristles

Over time, nylon bristles on a brush roll can become "soft" or flattened. To restore their agitation power, you can carefully use a heat gun or a high-powered hair dryer to warm the bristles and manually "tease" them back into an upright position. Additionally, check the bearings at either end of the roll. If they are stiff, a single drop of high-speed machine oil can prevent the motor from overheating.

The Scent and Sanitize Protocol

A vacuum not picking up often goes hand-in-hand with a vacuum that smells. To fix this, once your filters are dry, add two drops of essential oil (lemon or eucalyptus) to the pre-motor filter. This doesn't just mask odors; it acts as a mild surfactant to help break down organic particles that might be clinging to the internal plastic walls of the machine.

Mega FAQ: Expert Answers to Common Questions

1. Why does my vacuum have suction at the hose but not the floor?

This indicates a blockage in the lower duct or a problem with the brush roll. Check the "changeover valve"—the mechanical switch that diverts air from the hose to the floor head.

2. Can I use a shop-vac to clear my house vacuum?

Yes. If you have a stubborn clog in your upright vacuum's internal piping, a high-powered shop-vac can often "reverse-suck" the blockage out.

3. How often should I really replace my HEPA filter?

For average homes, every 6 to 12 months. If you have pets or allergies, every 4 months. HEPA filters cannot be washed unless specifically labeled "washable."

4. Why is my vacuum blowing dust back out?

This is a sign of a "leak" after the filtration stage or a incorrectly seated dust bin. It means air is bypassing the filters.

5. My vacuum shuts off after 5 minutes. What's wrong?

This is the Thermal Cut-Out. The motor is overheating, likely because a clog or dirty filter is forcing it to work too hard. Clear the obstruction and let it cool for 30 minutes.

6. Why is my brush roll not spinning on the carpet but spins in the air?

The belt is stretched. It has enough tension to spin the roll without resistance, but under the "load" of carpet fibers, it slips.

7. Does "suction" mean the same thing as "airflow"?

No. Suction (Water Lift) is the ability to lift weight; Airflow (CFM) is the volume of air moving. You need both to pick up dirt effectively.

8. Is it okay to vacuum up baking soda?

No. Baking soda is so fine that it clogs the pores of your filters almost instantly, leading to vacuum no suction.

9. Why does my vacuum sound like a jet engine?

Usually, this means the motor is "starved" for air. Check for a major clog in the primary intake.

10. Can I wash my vacuum's dust bin?

Yes, but remove all electronic components and sensors first. Ensure it is bone-dry before reassembly.

11. How do I know if my motor is actually burnt out?

If you smell ozone (a sharp, electric smell) and see sparks in the motor housing, the carbon brushes or the commutator are failing.

12. Why won't my vacuum push easily on my new carpet?

Modern "ultra-soft" carpets have very dense fibers that create a seal around the vacuum head. Look for a vacuum with "venting" or adjustable suction to break the seal.

Closing Thoughts on Vacuum Longevity

A vacuum cleaner is an investment in your home’s health. When you encounter a vacuum not picking up, it is rarely a sign that you need to spend hundreds of dollars on a new unit. Instead, it is an invitation to perform basic maintenance that the manufacturer assumes you are doing. By understanding the relationship between airflow, filtration, and mechanical agitation, you can troubleshoot almost any issue in under fifteen minutes.

Remember: air is the lifeblood of the machine. Keep the pathways clear, the filters clean, and the seals tight. If you follow the systematic guide provided here, your vacuum will not only pick up more debris but will last twice as long as the average consumer's machine. Maintenance is the difference between a tool that works and a tool that frustrates. Take control of your airflow today.